AI Vision Inspection

That Delivers Where Others Miss

Higher detection accuracy. Shorter deployment cycles.

Full data traceability. Actionable insights.

Introducing LIVIS, the world’s most advanced AI inspection system for manufacturing

LIVIS (Lincode Intelligent Visual Inspection System) conducts real-time quality inspections using advanced AI to enhance the accuracy and capabilities of traditional machine vision. LIVIS also offers a simple, no-code platform where manufacturing engineers, machine operators, and quality managers can train and deploy AI models for new parts, defects, and production lines.

Faster time-to-value

Return on Investment

Lower Total Cost

Lincode Intelligent Visual Inspection System (LIVIS)

Lincode Intelligent Visual Inspection System (LIVIS) is a proprietary Al-based visual inspection system for quality control. LIVIS empowers manufacturers and supply chain partners to supercharge quality inspection operations by improving reliability, expanding capabilities, simplifying data training, and automating analytics and reports. Whether deploying a new inspection station or integrating with existing cameras, LIVIS makes visual inspection faster, more accurate, and highly scalable.

SMARTER

Revolutionize traditional computer vision systems to:

-

Eliminate false calls and secondary inspections

-

Continuous learning of new parts and defects

-

Enable data traceability throughout quality systems

FASTER

Pre-trained AI models specific to manufacturing industries:

-

Train new parts and defects with just 30-50 images (avg.)

-

Real-time analysis in less than 40ms (avg.)

-

Eliminate manual logging of inspection results and reporting

SIMPLER

No-code platform for factory workers:

-

Train new parts and defects with a simple user interface

-

Auto-annotate defects to expedite new deployments

-

Integrate seamlessly with existing factory systems

Our Products

LIVIS Edge+

LIVIS Edge+ is Lincode’s proprietary runtime software that conducts real-time quality inspections of parts in production. Leveraging manufacturing-specific machine learning models, LIVIS Edge+ performs Al inferencing directly at the edge. The system easily integrates with industrial cameras and factory automation systems, enabling rapid deployment across production lines.

Primary Benefits:

- Unparalleled Accuracy. Reduce false calls and secondary inspections compared to traditional vision systems.

- Expanded Capabilities. Perform multiple types of inspections using the same cameras.

- Hardware Agnostic. Connect LIVIS with any industrial camera provider for brownfield or greenfield deployments.

- Seamless Integration. Integrate LIVIS to PLC, MES, ERP, and other factory control systems for advanced automations.

- Data Traceability. Capture images, inspection results, timestamps, and unique identifiers for full data traceability.

LIVIS Platform

LIVIS Platform is Lincode’s proprietary Al model training and inspection workstation management platform. Using a simple no-code interface, factory managers and operators can quickly train custom inspection recipes (Al Inspectors) to fit their production needs. LIVIS Platform connects with multiple LIVIS Edge+ applications to deploy these AI Inspectors and create quality inspection workflows.

Primary Benefits:

- Centralized Management. Train and deploy AI models, manage inspection workstations, and track data across production lines.

- Faster Deployments. Leverage 700+ AI models pre-trained on 800M+ data points for faster model training and deployment.

- Flexible Deployment Architecture. Access LIVIS Platform on the cloud or locally on premises.

- Minimal Operator Training. Onboard operators faster with user-friendly dashboards, encouraging widespread factory adoption.

- Actionable Insights. Leverage real-time dashboards, defects trends, and other analytics to improve production processes.

Core Competencies

Surface Defect Detection

Identify and classify surface defects, foreign objects & debris, and other defects reliably in real factory conditions.

Assembly Verification

Verify the presence/absence, orientation, and alignment of components to ensure proper assembly.

Anomaly Detection

Catch untrained anomalies with unsupervised learning models to spot new issues when they first occur.

Evolution of Visual Inspection

Traditional Machine Vision

Traditional Machine Vision systems have replaced many manual inspection processes. But these rule-based systems face many limitations that impact production:

- High false call rates

- Secondary inspections

- Controlled environments

- Limited data tracking

Standard AI Platforms

Many AI Platforms have overcome the limitations of rule-based systems. But most AI platforms require a significant amount of data, resulting in:

- Long training cycles

- Significant investment

- Pilot purgatory

Is Different

Is Different

LIVIS is a true deep learning platform, unbound by rule-based systems. LIVIS also comes with pre-trained models built on custom industry- and use case-specific datasets. As a result, LIVIS consistently outperforms traditional machine vision technology and other AI platforms in accuracy, latency, and speed.

Higher inspection accuracy • Simplified data training • Seamless integration • Accelerated deployments

Key Features and Benefits:

Unparalleled Accuracy

Increase the efficiency of traditional vision systems with LIVIS by improving reliability of inspection results and reducing false calls.

Expanded Capabilities

Supercharge legacy camera systems with LIVIS by expanding their native capabilities for quality inspection to include advanced defect detection, assembly verification, and label inspection.

Data Traceability

Capture images, inspection results, timestamps, and unique identifiers to comply with regulations and track data during production processes and beyond.

Hardware Agnostic

Connect LIVIS to existing cameras and factory control systems to improve quality inspection without expensive hardware upgrades or major process changes.

No-Code AI Platform

Train and deploy Lincode’s proprietary AI models for new parts, defects, and production lines using a simple, no-code interface.

Curated Datasets

Go live with new use cases in under a day by leveraging Lincode’s pre-trained AI models and industry-specific datasets for a wide range of manufacturing processes and materials.

Centralized Management

Manage workstations and data from production lines across the globe, whether deploying LIVIS on fixed camera stations, conveyers, robotic arms, or mobile devices.

Analytics & Reporting

Analyze inspection results to track performance and improve manufacturing processes, first pass yield, throughput, and overall equipment effectiveness.

Inspections

Pre-Trained AI models

Datasets

Countries

Industries

.png?width=800&height=634&name=image%20(5).png)

PCBA inspection

- Check for solder inspection, solder bridge, improper solder

- Identify missing components

- Ensure proper component placement for polarity

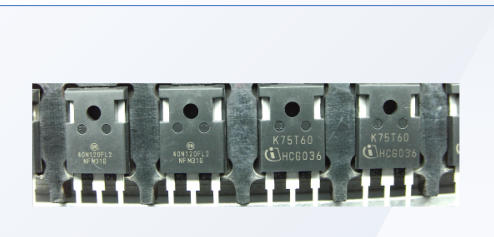

IGBT inspection

- Verify sequence position for array of components

- Check for presence of thermostat

- Validate vendor matching component

UPS inspection

- Identify Surface defects like scratches, dents

- Validate presence of fastener

- Verify alignment of cable connection

Piston Inspection

- Check for the presence/absence of pins

- Track the number of pins

- Defect analysis such as, scratches, porosity, black spot

- Color analysis

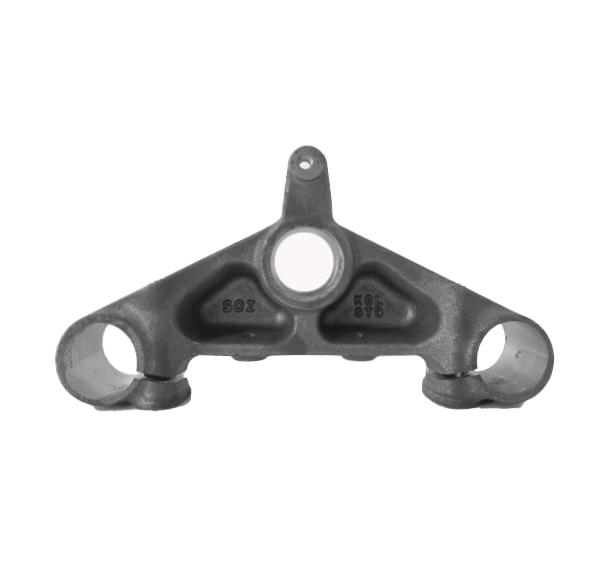

Stem Bracket

- Identify presence of holes

- Check for OCR

- Check for the presence of chamfer on the metal product

Clutch Plate

- Identify the rivet missing from the part

- Identify the rivet damage

- Track the pad damage

- Track the pin damage

- Identify the wrong assembly

Cylinder Block

- Detects dents and damages

- Recognizes chips

- Captures and verifies OCR readings

- Detects excess Loctite

- Identifies Foreign Object Debris (FOD)

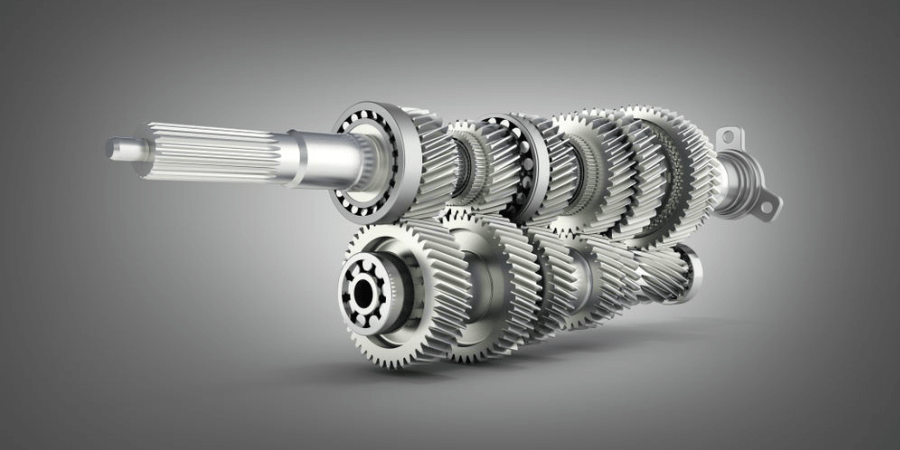

Transmission Gears

- Detects rust formation

- Identifies dents

- Recognizes dirt

- Inspects for full, partial, or zero grinding

- Detects incorrect welding

Cylinder Head

- Detects scratches, dent marks, and thread damage

- Identifies chips in the oil gallery hole

- Recognizes burrs at the injector bore intersection

- Detects foreign particles

Input Shaft

- Identifies shaft variants

- Detects notches

- Verifies proper assembly sequence

- Identifies rust and burrs

- Detects chip-off

Front/Back Side Door

- Check for proper pin placement

- Detect the presence of white papers

- Inspect twitter markings

- Verify hand rest installation

- Ensure red light functionality

Diesel Injector Needle

- Detects grinding defects

- Identifies delamination

- Recognizes grinding marks

- Detects tip damage

- Identifies scratches

- Check for droplets

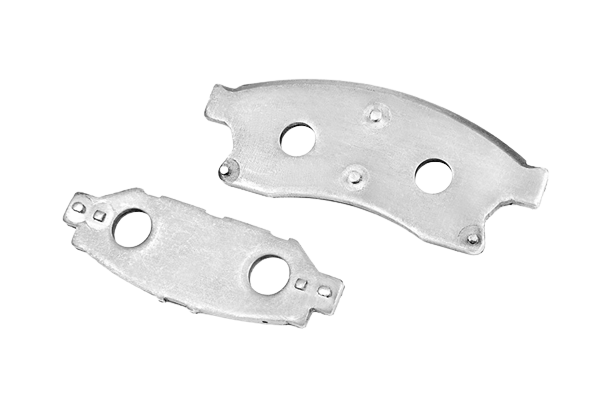

Brake Backplate

- Detect double punch marks

- Identify excess material

- Inspect for improper coating

- Recognize scratches

- Detect dents

- Identify cracks

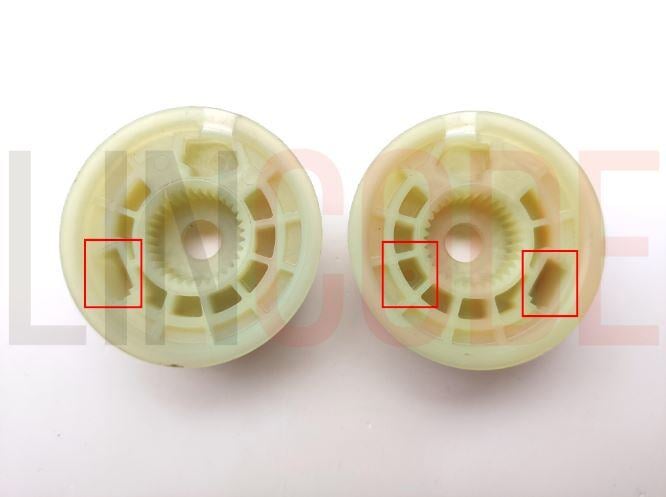

Window Rollers

- Classify parts into LH and RH

- Detect surface roughness

- Identify damages

- Recognize flash

- Detect discoloration

Car Bumper

- Detect surface defects

- Identify shape deformations

- Verify the presence and absence of clips, screws, rivets, nut springs, sensors etc

- Inspect for aesthetic defects

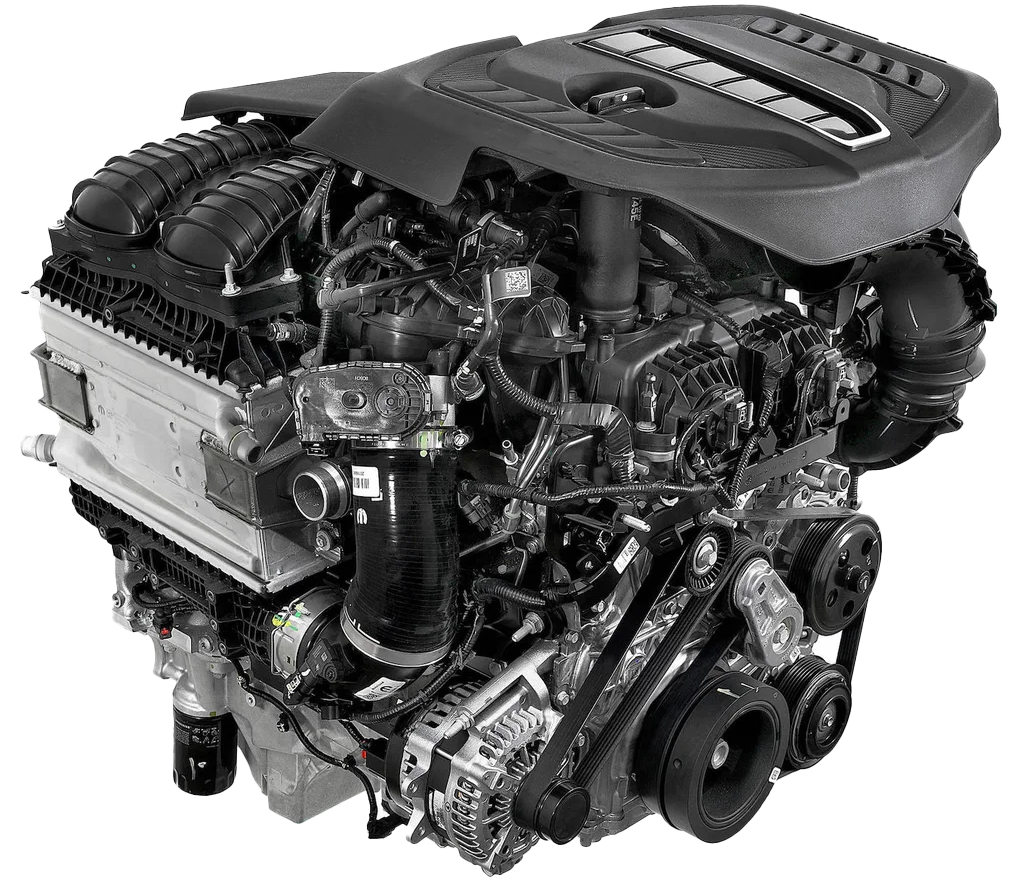

Engine

- Verify assembly accuracy

- Check for the presence and absence of child parts and features

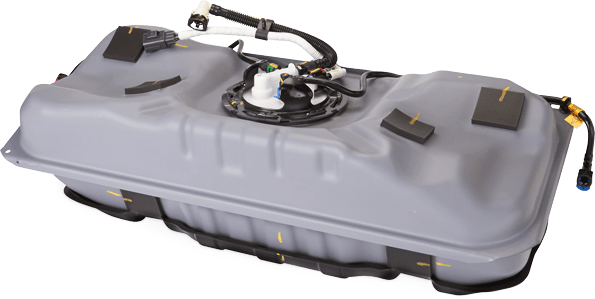

Fuel Tank

- Detect holes

- Identify dents

- Recognize black spots

- Detect rust formation

- Verify OCR readability

- Identify damages

Engine Valve

- Detect coating loss

- Identify surface roughness

- Recognize surface defects

- Check for dimensional errors

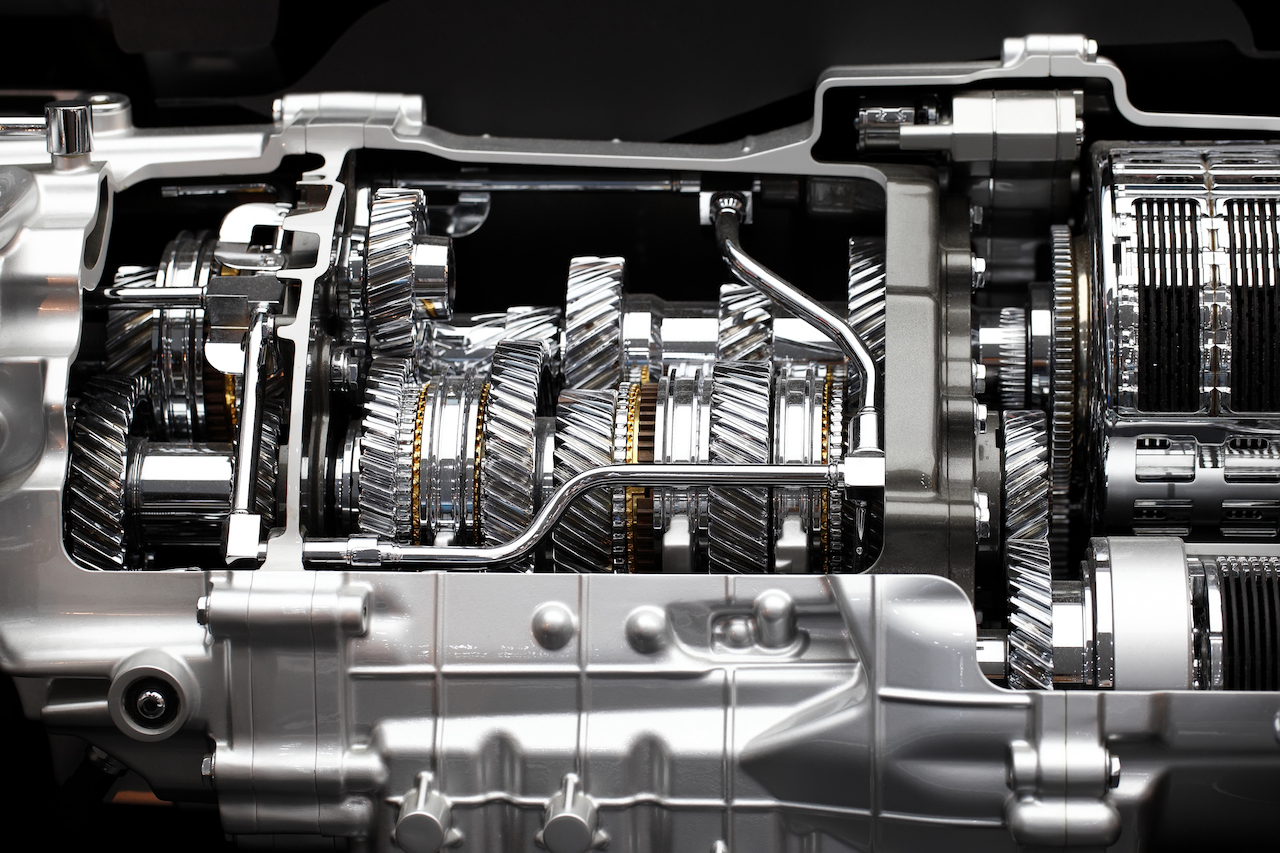

Gearbox

- Identify plastic deformation

- Detect abrasion

- Recognize cavitation

- Inspect for cracks

Differential

- Detect porosity

- Identify microcracking

- Identify microcracking

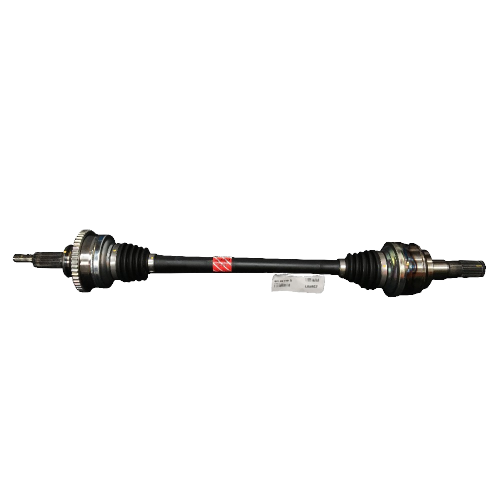

Drive Shaft

- Identify cracks in the rubber bearing

- Detect pipe deflection

- Check for slotted joint backlash

Transfer Case

- Identify dents

- Detect cracks

- Recognize porosity

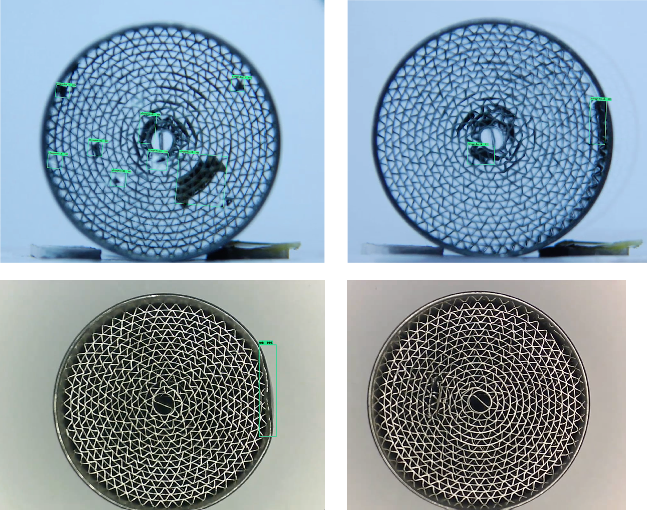

Catalyst Inspection

- 360 degrees inspection

- Detect Plugged cells

- Identify surface defects like dents, bends, coating defects

Connecting Rod Inspection

- Inspect for bolt plan burrs and burr in bush

- Detect crack marks and chip offs

- Identifying chamfer presence and absence

- Capturing the Needle print OCR

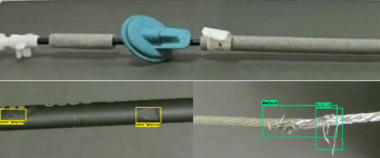

Wiring Harness

- Identify rubber surface defects like chip off, dents and breakage

- Detect surface defects on child parts

- Detect metal breakages

Turbo Charger (Housing components)

- Identify presence and absence of holes and chamfer

- Detect surface defects like dents and scratches

- Classify part accurately

Cockpit or Dashboard PDI

- Presence of parts as per variant

- Identifying Surface defects like scratch, crease, wrinkles, glue presence and more

- Detecting Stitching and paint defects

Paint inspection

- Identifying surface defects like scratches, pinholes

- Detect Dirt and rate orange peel

- Detect paint runs and sags

Weld inspection

- Identifying porosity and burn through

- Detect spatter and undercut

- Track absence of welds

Sealant Inspection for Door and Hood

- Detect excessive or missing sealant

- Verify mastic count

- Ensure gap consistency of hemming and mastic sealant

Body/ Stud inspection

- Detect surface detects like dents, cracks

- Verify stud counts and detect missing studs

- Validate for stud alignment

Testimonials

We have been using Lincode’s AI-based solution in our facility for the last 3 years and have observed a drastic improvement in performance:

- Inspection cycle time reduced from over 60 seconds to just 5 seconds per unit.

- False call rate reduced from approximately 30% to less than 3%, greatly improving accuracy and process reliability.

The ease of programming and flexibility of the system are the features we value most. Engineers can easily set up and teach the system using just a few sample images, eliminating the need for time-consuming programming typically required in rule-based systems. This makes the system highly adaptable and user-friendly.

Compared to other inspection systems, Lincode’s LIVIS system delivers lower false call rates and much better adaptability to product-specific needs. It is by far the best solution we have used for customized inspection requirements across a variety of products.

Siraj Puthanpurayil, Senior General Manager Manufacturing Technology, Global Supply Chain

Schneider Electric

As pioneers in visual quality inspection using AI, Lincode has helped us solve many challenges in BIW automation lines where traditional vision systems fail to support our applications. The Lincode team is highly flexible to our requirements and has extended their services beyond the initial specifications to help solve the problems on-site.

Rajsekhar Jaypal, AVP, Welding Systems

DiFACTO Robotics and Automation

Since we started using the Lincode inspection system, we’ve had a significant increase in productivity. The system can detect defects in the bolt no matter how the part is placed, along with missing pins. This has reduced our manual efforts and increased operator efficiency. We are very satisfied with the system and will certainly work with Lincode on other projects.

Andreas Nußmüller, Managing Director

Nußmüller Montagetechnik

.png?width=79&height=66&name=Vector%20(20).png)

We are into Robotic Integration, Robotic Simulation, Robotic Programming and Robotic Onsite training. We know Lincode from the past 2 years who are into vision inspection with AI and Deep Learning. We are amazed with the technology they are using with basic cameras and using AI which is far, far ahead of the conventional imaging process. They have a wonderful software team and with them we are integrating the vision system to any brand of robots. So basically we want to use their expertise and associate with them for robotic-based inspection systems and place with the help of vision and vision-based tracking systems.

VP of Finance

Automotive Company

Case Studies

Awards

Michigan Celebrates Small Business

Best Small Business Award 2024

Centrepolis Accelerator

Best Manufacturing Technology 2024

Advanced Manufacturing Expo

Pitch Competition Winner 2023

-1.png?width=1112&height=324&name=logos%20(2)-1.png)

-1.png?width=1068&height=357&name=logos%20(1)-1.png)

.webp?width=180&height=101&name=north%20american%20(1).webp)